How Are Ceramic Tiles Made?

Ceramic tiles come in so many different varieties, shapes, sizes, colours, materials, and textures that it can be awe inspiring to look at them all and wonder not only how people design them, but to wonder how they get made.

The Ten Steps For Making Ceramic Tiles

Humanity has been making ceramic tiles for thousands of years. Egyptians, Assyrians, and Babylonians were mastering the craft of creating ceramic tiles a very long time ago. Overtime methods have changed — partially due to technological advances — and we would like to explain the 10 common steps people now follow to create these tiles.

Step One: Sourcing Raw Materials

The first step involves the manufacturer collecting the raw materials that they will then be able to use to create the different ceramic tiles they would like, including porcelain tiles.

Step Two: Batching

Batching is the process of obtaining the raw materials and determining what the composition of the tile’s body is going to be. Batch calculations are used to determine the chemical and physical properties of the tile.

Step Three: Mixing And Grinding

The ingredients of the tile are measured, weighed, and added into a mixer. Once they are added they will be mixed and grinded, to turn them into a fine body slip liquid to help with the next processes.

Step Four: Spray Drying

If the mixing and grinding process used wet milling, spray drying will be used to remove the water from the mix. This process involves a special machine to dry the slip into Granules. .

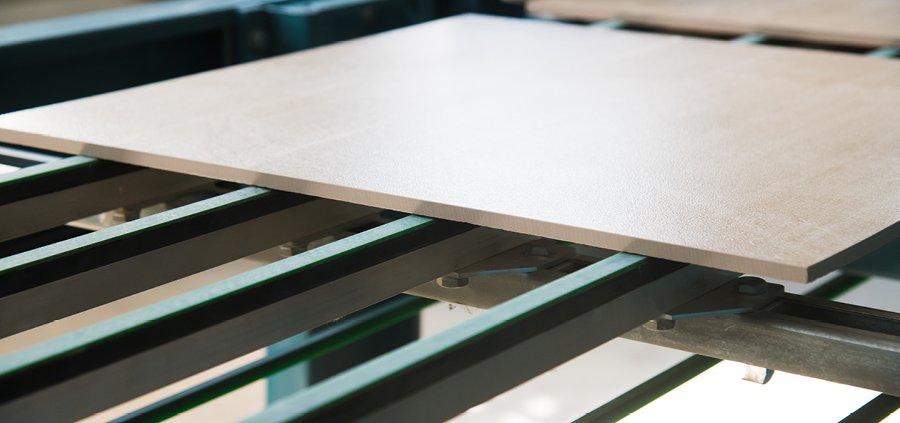

Step Five: Forming

This is the process where the tiles get their shape. The mixture will be put into a forming die so it can be formed. There are various ways that a tile may be formed depending on what the materials are.

Step Six: Drying

Now that the tiles are formed the drying process can start. The specific drying method will depend on the materials of the tiles. However, in all cases they must be dried slowly to prevent cracks and shrinkage.

Step Seven: Glazing

This is where the tile gets its beauty. This is where a tile will be given a print or pattern. Then it will get a glaze or two over the top for durability.

Step Eight: Firing

This is the final step that will affect the tile itself. Firing puts everything in place. This step ensures all moisture is removed and sets the glaze and tile in place.

Step Nine: Quality Assurance

This is a step that most manufacturers will employ to ensure their products are meeting a high quality standard. This process also allows manufacturers to notice if there are any common issues that may be occurring along the factory line.

Step Ten: Shipping

Customers will now be able to buy their ceramic tiles and have them shipped to them, so they can enjoy all of the benefits of ceramic tiles for their next renovation project.

Talk Tiles With The Professionals

While your options for tiles, timber and carpet are almost limitless, selecting the right type for your home certainly isn’t an easy feat. With each space, comes a different preference or priority: are you chasing style, functionality, or simply want to stay within the budget?

In operation for over 25 years, at Tile Wizards we pride ourselves on getting you more – for less. We pioneered the warehouse format, and our stores are purposefully designed to make your selection easier, and ultimately offer our customers quality, price and the right advice.

While we specialise in options for tiles, carpets, timber and a wide variety of hybrid flooring materials, our services have just expanded even more. For customers who reside locally on the Sunshine Coast, In Coffs Harbour, Brisbane, and Adelaide, we also stock a range of vanities and tapware products in store, making it easier than ever to start conquering DIY projects at home.

Even if you are just after some honest and friendly advice – please don’t hesitate to get in touch with us at Tile Wizards today for a free quote. We’re able to work with you in order to bring your dream flooring solution to life.